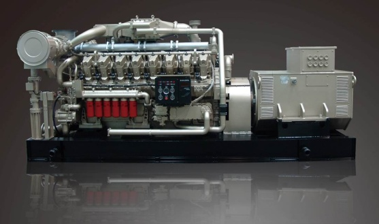

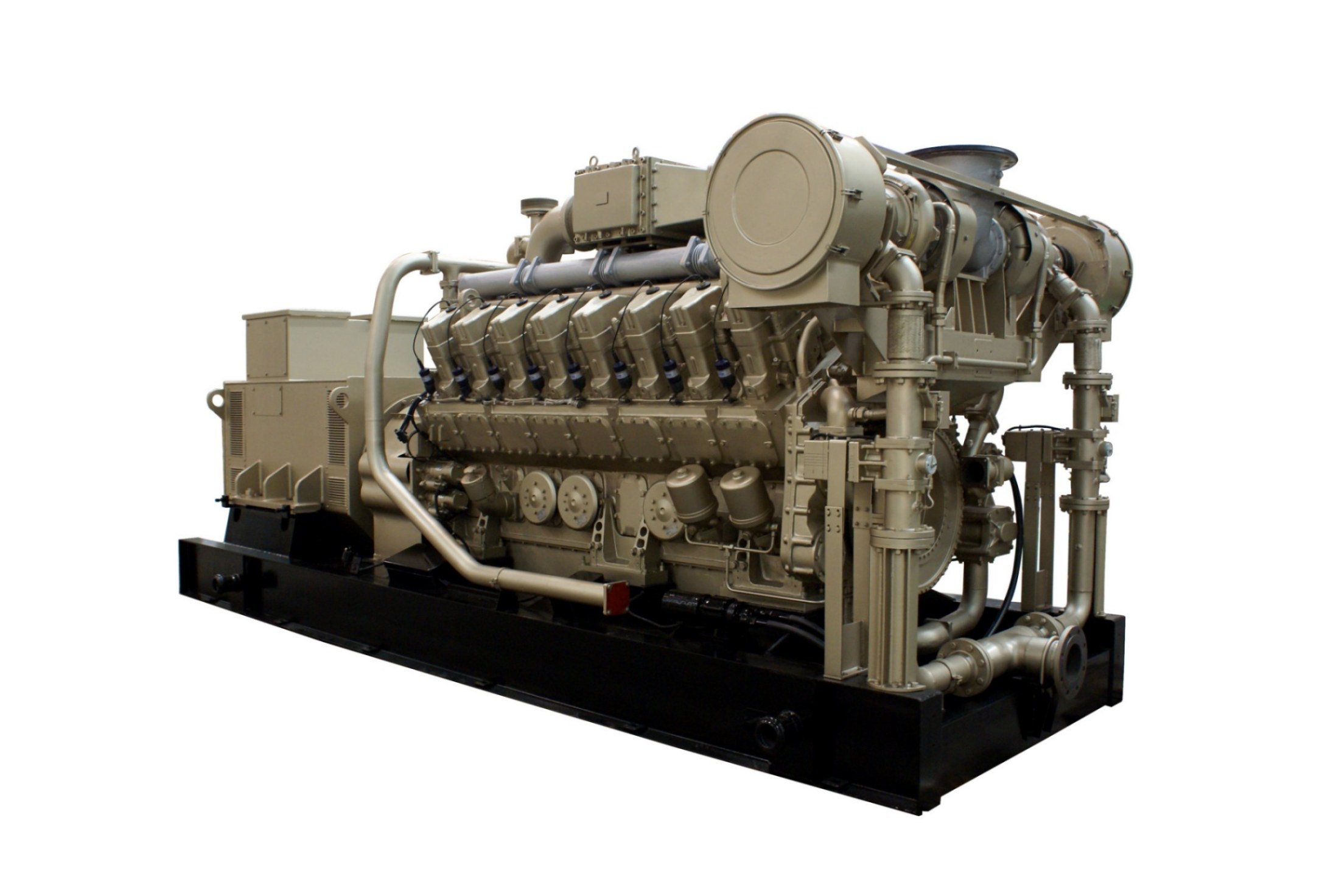

900kW Gas Engine Generator

1、High quality

2、Long usage life

3、Easy operation

4、Low maintenance cost

5、High intelligence with low engine speed

6、Low fuel consumption

7、Low gas quality requirement

8、Tough environmental adaptability

9、High stability and low fluctuation

Jichai gas engine generator is designed and manufactured to be excessive quality, lengthy utilization life, convenient operation, low protection cost, excessive Genius with low engine speed, low gas consumption, low fuel first-class requirement, difficult environmental adaptability, excessive steadiness and low fluctuation. The gas engine generator is suited for industrial energy solution.

900KW Natural Gas Generator Specification

Type | 900GF-T |

Rated Power | 900kW |

24 hrs Continous power | 765kw |

Rated Voltage | 400 |

Rated Current | 1260 |

Rated Frequency | 50Hz |

Supply Connecting | 3 phases 4 wires |

Rated Speed | 1500r/min |

Rated Power Factor | Cosφ 0.8(lagging) |

Eng. Oil consumption | ≤0.3g/kw h |

Efficiency | 38 % |

Starting Method | DC24V Electric |

Noise dB(A) | ≤105 |

Ref. Overall Dim.(LBH) | Open type: 6000×2200×2400 mm |

Ref. Weight | 14500kg |

Engine Technology Specification

Type | 12M33D900E310NG |

Number of cylinders | 12 |

Number of Valves | 48 |

Cylinder Arrangement | V type |

Cylinder diameter x stroke | 150×185 mm×mm |

Total Displacement | 39.2 L |

Fuel System | Electronically controlled low pressure pre-turbo mix |

Intake Type/Aspiration | Turbocharged and inter-cooled |

Compression ratio | 11 |

Rated Power,kW | 900 |

Rated Speed,r/min | 1500 |

Overall Dimensions (L x W x H) | 2651×1338×1631mm |

Engine Net weight | 3390kg |

Mean Piston Speed | 9.25m/s |

Mean effective pressure | 1.837 MPa |

Maximum Burst Pressure | ≤13 MPa |

Minimum No-load Speed | 700-750 r/min |

Ignition Order | A1-B2-A5-B4-A3-B1-A6-B5-A2-B3-A4-B6 |

Sense of Rotation | Anticlockwise(In the Face of Flywheel) |

Min.cold start temperature without auxiliary starting | -5°(C) |

Min. cold start temperature with auxiliary starting | -10°(C) |

Remark: All parameters may changed without prior notice as technical upgrade.

Alternator Technology Specification

Alternator Model | EG450-800N-6 |

Rated capacity | 1000kVA |

Rated power | 800kW |

Voltage | 400V |

Frequency | 50Hz |

Rated speed | 1500r/min |

Recovery time | 1s |

Waveform : THD | <3% |

Winding pitch | 5/6 |

Voltage regulation | +/- 1% |

A.V.R. model | EVC600 |

Duty | S1 |

Number of poles | 6 |

Class of insulation | H |

Class of temperature rise | H |

Excitation | Brushless |

Rated power factor | 0.8 |

Efficiency of 25% load | 94.25 |

50% load | 95.81 |

75% load | 95.98 |

100% load | 95.62 |

110% load | 95.38 |

Short-circuit ratio | 0.681 |

Direct axis synchronous reactance | 2.145 |

Quadrature axis synchronous reactance | 0.971 |

Direct axis transient reactance saturated | 0.136 |

Direct axis subtransient reactance saturated | 0.099 |

Quadrature axis subtransient reactance saturated | 0.115 |

Zero sequence reactance unsaturated | 0.031 |

Leakage reactance | 0.061 |

Negative sequence reactance saturated | 0.11 |

Open circuit time constant | 2.492 |

Short-circuit transient time constant | 0.157 |

Subtransient time constant | 0.003 |

Armature time constant | 0.026 |

Stator winding | 6ends |

Rotor | With damping cage |

Overload | 110% rated load for 1 hour |

Method of cooling | IC01 |

Ambient temperature | -15~40ºC |

Sense of rotation | Clockwise direction |

Type of construction | Double |

Degree of protection / enclosure | IP23 |

Maximum overspeed | 1250rpm 2mins |

Air intake system Specification

Air intake temperature rise | 5ºC |

Air intake restriction dirty filter | ≤5 kPa |

Recommended air flow @ PRP | 3807 kg/h |

Min. diameter of intake pipe | 160 mm |

Intercooling system Specification

Max. intake temperature | 55ºC |

Max. difference between intake temperature &ambient temperature | ≤30ºC |

Max. intake pressure drop of intercooler | 12 kPa |

Cooling system Specification

Permitted lowest coolant temperature of engine running | 50ºC |

Min. inside diameter of coolant outlet pipe | 45mm |

Coolant alarm temperature | 95ºC |

Thermostat opening temperature/full open temperature | 80/92ºC |

Min. pressure in cooling system | 50kPa |

Coolant capacity of the engine | 75.94 L |

Exhaust system Specification

Max. exhaust back pressure | 7.5kPa |

Max. exhaust temperature before turbocharger | 730ºC |

Max.exhaust temperature after turbocharger | 680ºC |

Exhaust flow @ PRP | 3968kg/h |

Min. diameter of exhaust pipe | 220mm |

Max. bending moment of exhaust gas exit flange | 10Nm |

Lubrication system Specification

Oil capacity Min / Max | 120/146L |

Oil pressure in normal condition idle speed | ≥200kPa |

Oil pressure in normal condition at rated speed | 400-650 kPa |

Lowest oil pressure alarm value | 200kPa |

Lowest oil pressure shutdown value | 160kPa |

Max. oil temperature | 105kPa |

Oil flow | ≥392 L/min |

Oil fuel consumption ratio based on engine fuel consumption data | ≤0.3% |

Fuel system Specification

Min. gas resistance of the fuel mixer inlet | 2kPa |

Max. gas resistance of the fuel mixer inlet | 7kPa |

Max. allowed fuel inlet temperature | 50ºC |

The recommended min. gas inlet pipe diameter | 40mm |

Electrical system Specification

The max. resistance of the starting circuit | 0.002Ω |

Min. sectional area of the wire | 70mm² |

Starter power/ Staring voltage(Basic Engine) | 8.5/24kW/V |

Heat balance test data under rated working condition(10.3ºC)

Coolant inlet/ output pressure | 0.4/215 kPa |

Coolant flow | 80.6 m3/h |

Coolant inlet/output temperature | 94.1/89ºC |

Intercooler inlet/output temperature | 147.7/41.4ºC |

Intercooler inlet/output pressure | 200/151 kPa |

Engine heat | 2230 kJ/s |

The heat loss by the exhaust | 703.3 kJ/s |

The heat loss by the coolant | 401.6 kJ/s |

Intercooler heat dissipating capacity | 112.8 kJ/s |

Radiation heat of the engine surface | 112 kJ/s |

Note: Because of test errors and other reasons, the surface radiation heat is 5%of the engine total heat. | |

After Sale Service

1. Professional engineers provide pre-sales technical consultation for users

2. Cooperate with users to install and debug the unit

3. Maintenance engineers are available to provide technical assistance at any time

Packing&Delivery

WOODEN CASE/PLYWOOD CASE

1) Genset would be blanketed with plywood bins ;

2) Control panel, batteries, electric powered cables are packed with plywood packing containers or cartons;

3) Exhaust pipes, engine mufflers are put in the container except packing.

We typically undertake delivery by way of bulk cargo, container, packing Standard export packing, or custom-made packing as your request. We will prepare the most comparatively cheap transportation mode in accordance to the volume of products. All merchandise have long past via strict inspection and are in top situation earlier than shipment. We attempt for a hundred percent client delight on each sale we close.

Production line

Production line

Exhibition

Other Products