1875kVA Biogas Engine Generator

1、Closed loop electronic control, accurate air-fuel ratio control

2、Lean combustion technology supercharged pre mixing

3、High energy digital ignition module spark plug ignition

4、Automatic grid connection, remote transmission function, remote monitoring

5、Perfect safety protection device

The biogas generator adopts - L20V190ZL engine, which is one type of pretty intelligent, low warmth consumption, excessive reliability, low emission, lengthy lifetime 20V fuel engine.

Genset model | 1600GF-Z |

Alternator model | 1FC series,siemens technology.Brushless excitation,Automatic voltage regulation. |

Panel model | GPL1600 |

Rated power | 1600kW |

Rated voltage | 400V/480V/6300V/10500V/13800 |

Rated frequency | 50/60HZ |

Rated power factor | 0.8 |

Wiring mood | 3 Phase 4 Wire/3 Phase 3 Wire |

Stabilized voltage regulation | ±2.5% |

Transient state voltage regulation | +20%(-15) |

Voltage stabilization time | ≤1.5s |

Fluctuation rate of voltage | ≤1% |

Transient state frequency regulation | ≤±10% |

Frequency stabilized time rate | ≤7s |

Fluctuation rate of frequency | ≤0.5% |

Overall dimension | 7500mm*2300mm*2800mm |

Net weight | 29000kg |

Engine model | L20V190ZLZ-2 |

Type | Four strokes,Vshape,turbocharged intercooling,spark plug ignition. |

Number of cyliner | 20 |

Bore | 190mm |

Stoke | 255mm |

Total displacement | 144.6L |

Rated speed | 1000r/min |

Rated power | 1750KW |

Idle speed | 700r/min |

Gas pressure | 10-40KPa |

Gas consumption | ≤8600kJ/kW·h |

Oil consumption | ≤0.6g/kW·h |

Exhaust tem.(before turbine) | ≤640℃ |

Water oulet temperature | ≤85℃ |

Water inlet temperature of intercooler | <45℃ |

Oil temperature | <90℃ |

Stabilized speed droop | ≤5 |

Cooling mood | Open type-cooling tower/closed type-vertical or horizontal radiator |

Lubrication method | Pressure and splash lubrication |

Starting mood | DC24V Electric Start |

Crankshaft rotation | Counter-clockwise(face to flywheel) |

Product Service

1. Develop the most suitable preliminary plan based on the specific needs of the customer

2. Provide engineering design and debugging training for users

3. Improve after-sales service

Packing&Delivery

1) Gas engine generator would be protected with plywood containers ;

2) Control panel, batteries, electric powered cables are packed with plywood containers or cartons;

3) Exhaust pipes, engine mufflers are put in the container barring packing.

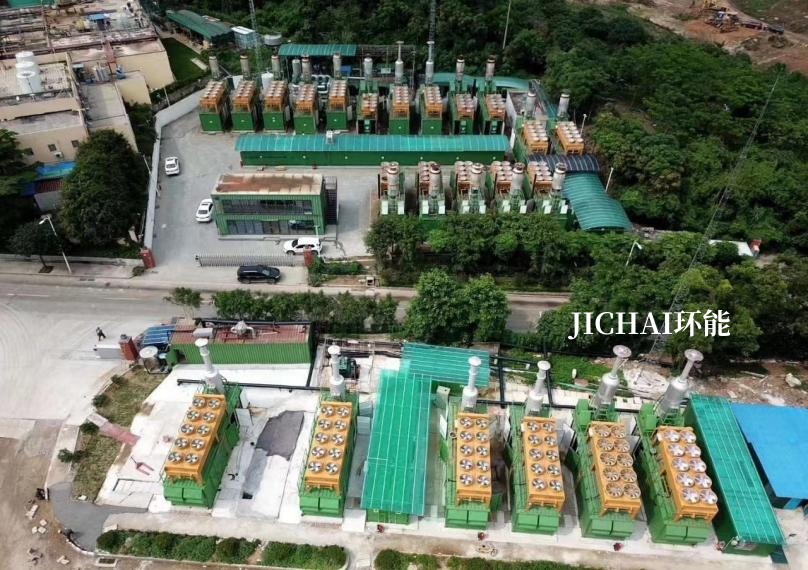

Production line

Production line

Other Products