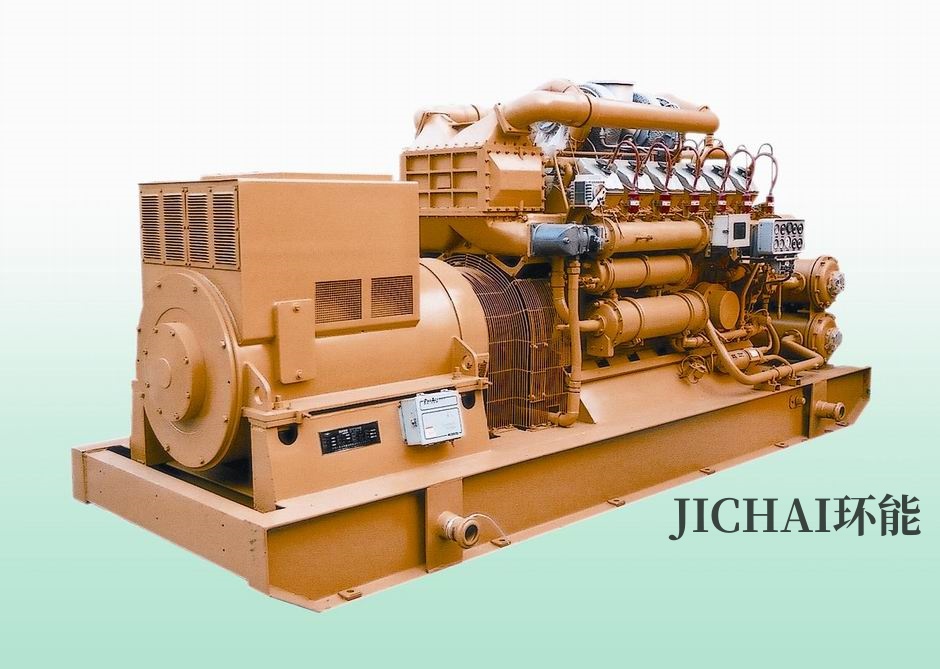

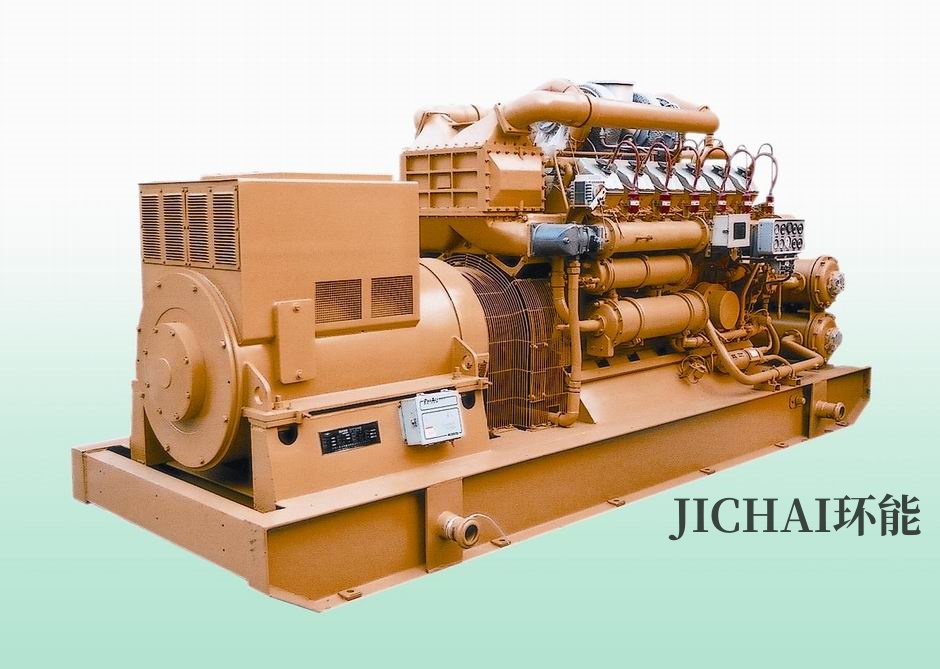

625kVA Biogas Engine Generator

The 500kW 625kVA Biogas Generator is geared up with M12V190ZL Gas engine as unique power,which is designed and manufactured to be excessive quality, lengthy utilization life, convenient operation, low upkeep cost, excessive talent with low engine speed, low gas consumption, low fuel great requirement, difficult environmental adaptability, excessive balance and low fluctuation. The generator is perfect for industrial energy solution.

The 500kW 625kVA Biogas Generator is geared up with 12V190ZL Gas engine as special power,which is designed and manufactured to be immoderate quality, prolonged utilization life, handy operation, low renovation cost, immoderate brain with low engine speed, low gas consumption, low gas excellent requirement, tough environmental adaptability, immoderate stability and low fluctuation. The generator is best for industrial power solution.

MAIN SPECIFICATIONS OF GAS GENERATOR SET

Model | 500GF-M | Gas Engine Model | 12V190ZL | |

Rated power | 500kw | Alternator | synchronous brushless generator | |

Rated voltage | 400 V | Insulation class | F | |

Rated speed | 1000rpm | Voltage regulation | Automatic | |

Rated frequency | 50Hz | Class of protection | IP23 | |

Rated current | 902A | Cooling method | Water cooling with radiator and fan | |

Power factor | 0.8 Lagging | Dimension (mm) | 5750×2650×2500mm | |

Control mode | Electric control | Net Weight (kg) | 14500 Kg |

MAIN ELECTRICAL PERFORMANCE OF THE GAS GENERATOR

Voltage | |||

Stabilized regulation | Instantaneous regulation | Recovery time | Fluctuation |

±2.5% | +20% | 2 S | 1% |

Frequency | |||

Stabilized regulation | Instantaneous regulation | Recovery time | Fluctuation |

0-5% adjustable | ≤±10% | < 7 S | 1% |

MAIN SPECIFICATIONS OF GAS ENGINE

Type | M12V190ZL |

Number of cylinders | 12 |

Cylinder Arrangement | Vee,60° |

Cylinder diameter x stroke | 190×210 mm |

Total Displacement | 71.5 L |

Intake Type | Turbocharged and inter-cooled |

Rated Power,kW | 750 |

Rated Speed,r/min | 1000 |

Biogas input pressure,kPa | 5-10 |

Exhaust Temperature before turbocharger,ºC | ≤650 |

SAFETY AND PROTECTION DEVICE OF THE GENERATOR

Output voltage too low/too high alarm and stop | Single phase connection trouble alarm and stop |

Frequency too high/too low alarm and stop | Cooling water temp high alarm |

Reverse power alarm and break brake | Lubrication oil temp too high alarm |

Overload alarm and break brake | Lubrication oil pressure too low alarm and stop |

Over speed alarm and stop | Battery voltage too low alarm |

Blast prevention of air inlet and crankcase | Gas leaking protection |

CONTROL PANEL

Control panel is panel type, vertical structure, model is GPL500. Control panel is equipped with meters showing various parameters of operating status, automatic air switch and timer. All of the electric cells possess three-proof functions.

The Generator possesses the following automatic monitoring and protective functions:

A) Audio or visual alarm for:

- High oil and water temperature

- Low oil pressure

- Over current

- Short circuit

- Over-speed

- Reverse power

B) Shut-off for:

- Low oil pressure

- Over-speed

- Short circuit

- Over-speed

- Reverse power

C) Trip-off for:

- Over-current

- Short circuit

- Reverse power

The generator can not only supply power directly to load but also can be paralleled running.

OPTIONAL DEVICE

Steel Soundproof Container (sound attenuated canopy)

CHP/ Cogeneration/CCHP Trigeneration

Synchronization Parallelling Panel

Oil and Water Heater

Packing&Delivery:WOODEN CASE/PLYWOOD CASE

1) Genset would be covered with plywood boxes or cartons ;

2) Control panel, batteries, electric cables are packed with plywood boxes or cartons;

3) Exhaust pipes, engine mufflers are put in the container without packing.

After Sale Service

1. Providing container design and power distribution design

2. Providing guidance for installation and debugging

3. Providing technical training and consultation for users' operation and maintenance personnel

4. Guiding maintenance

5. Establishing customer profiles for end users and track services

6. The company provides spare parts, and maintenance engineers provide technical assistance at any time

Packing&Delivery

Production line

Exhibition

More Products