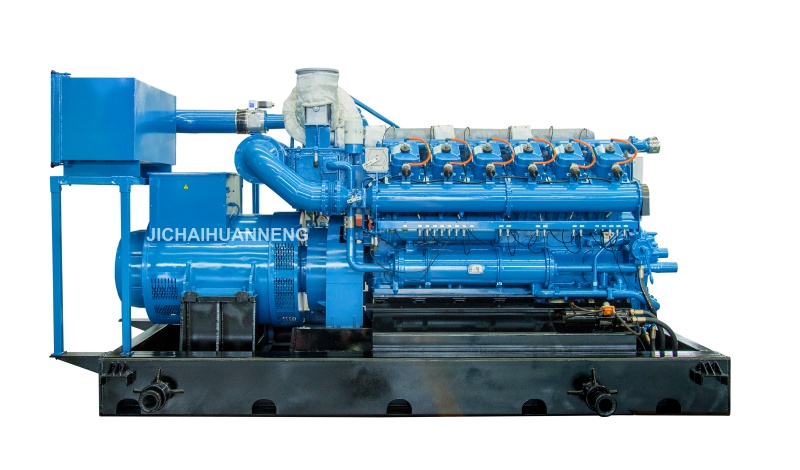

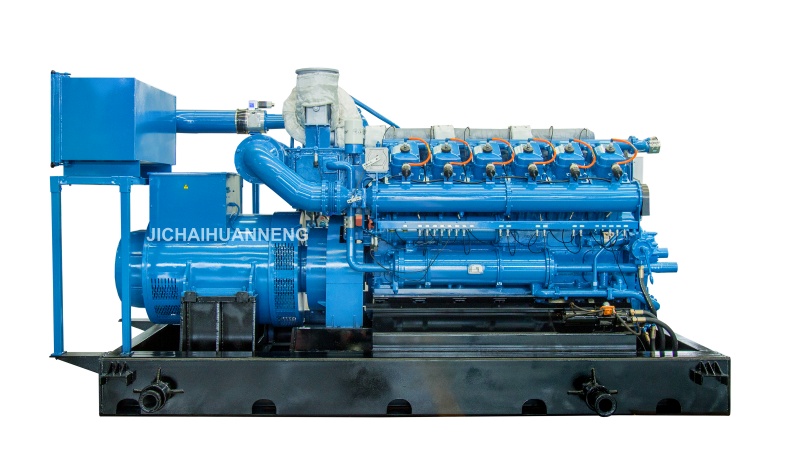

700kW Syngas Engine Generator

700GF2-M Generator set is a proven unit which has been put into market and verified for many years, and has feature of high thermal efficiency, high load capacity and anti-load surge ability with universal parts and low maintenance cost.

The 700GF2-M syngas engine-generator adopts Jichai 12V190 Engine and Siemens technology alternator. This generator set utilizes advanced control system, closed-loop electronic control technology, air-gas mixed technology before turbo-charge and lean burn technology, follows IS09001 Quality System.

700GF2-M Generator set is a proven unit which has been put into market and verified for many years, and has feature of high thermal efficiency, high load capacity and anti-load surge ability with universal parts and low maintenance cost.

Main specification of 700kW syngas generator | |

Brand | JCHN |

Model | 700GF2-M |

Rated Power(kW/kVA) | 700/875 |

Optimal output power during continuous operation(kW) | 560-600 |

Rated Power(V) | 6300 |

Rated frequency(Hz) | 50 |

Rated Power Factor | 0.8(lagging) |

Noise(dB(A)) | ≤108dB(1m away from the generator set) |

Unit volume gas power generation(kW.h/Nm3) | ≥1.8 |

Maximum fuel consumption(Nm3/h) | 350 |

Lubricating oil consumption rate(g/kW.h) | ≤1.0 |

Efficiency(%) | ≥35 |

Exhaust temperature(℃) | ≤580℃ |

Size(L×W×H)(mm) | 5500×1700×2295 mm |

Weight(kg) | 14500kg |

Dynamic performance indicators of power output | |

Setting range of no-load voltage(%) | 95~105 |

Steady-state voltage regulation rate(%) | ≦±2.5 |

Transient voltage regulation rate(%) | -15%~+20% |

Voltage recovery time(s) | 5 |

Voltage fluctuation rate(%) | ≦1.5 |

Transient frequency adjustment rate(%) | ≦+15 -12% |

Frequency stabilization time(s) | ≦15s |

Technology specification of syngas generator | |

Brand | JCHN |

Structural style | 12 cylinder V-type, spark plug ignition, turbocharged intercooler |

Model | 12V190ZL |

Cylinder diameter x stroke, mm×mm(mm) | 12-190×210 |

Displacement(L) | 71.5 |

Rated Power(kW) | 700 |

Rated speed(r/min) | 1000 |

Speed regulation method | Electronic speed regulation |

Ignition method | The ignition module controls the spark plug ignition, using the split type spark plug |

Air intake method | Independent intake (mixing air and gas inside the cylinder) |

Burning method | Lean burn |

Starting method | 24VDC electric starting motor |

Cooling method | Horizontal radiator |

Overhaul period(h) | ≥25000 |

Technology specification of Engine | |

Rated capacity(kVA) | 875 |

Rated voltage(V) | 6300 |

Rated frequency(Hz) | 50 |

Rated Power Factor | 0.8(lagging) |

Wiring method | Three-phase three wire system |

Insulation class | H |

Protection class | IP23 |

Unit management, control and display system | |

operating method | Automatic/Manual/Remote Monitoring |

management system of Generator | TEM |

Data transmission interface | RS485 |

generator operation data display | Local monitoring cabinet LCD screen display and backend monitoring computer (capable of monitoring the operating parameters of multiple units) |

Electronic speed control system | PISC |

Power output and control system | |

Automatic grid connected control cabinet | Implementation of local monitoring cabinet |

Data diaplay | Local monitoring cabinet LCD screen |

Control module | ComAp IG |

Data transmission interface | RS485 |

Gas regulation and control system | |

Gas pressure regulator | Automatic pressure regulating valve |

Fuel control mode | butterfly valve |

Maximum intake pressure of gas(kPa) | 40kPa |

Minimum intake pressure of gas(kPa) | 10kPa |

Maximum gas temperature(℃) | ≤40 |

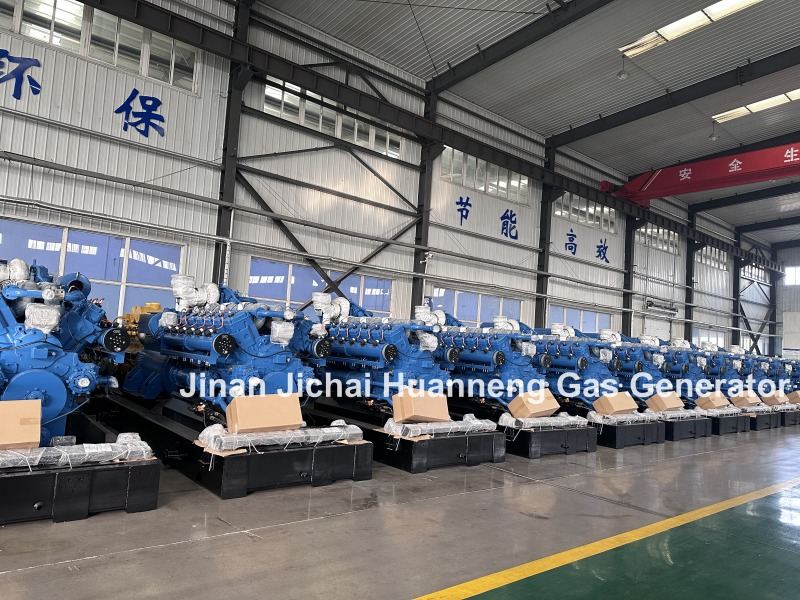

Project Cases

Pre-sale service

Arrange technicians to site for on-site survey under free cost, and provide Layout Drawing, Circulation Cooling System Process Flow Chart, Installation Drawing, Foundation Drawing, Primary Electric Wiring diagram, etc as per actual site condition and meet the requirement of design and construction.

Certification

Delivery

If have any questions,pls contact us

E-mail:anna_jichai@126.com

Whatsapp:+8617753129375