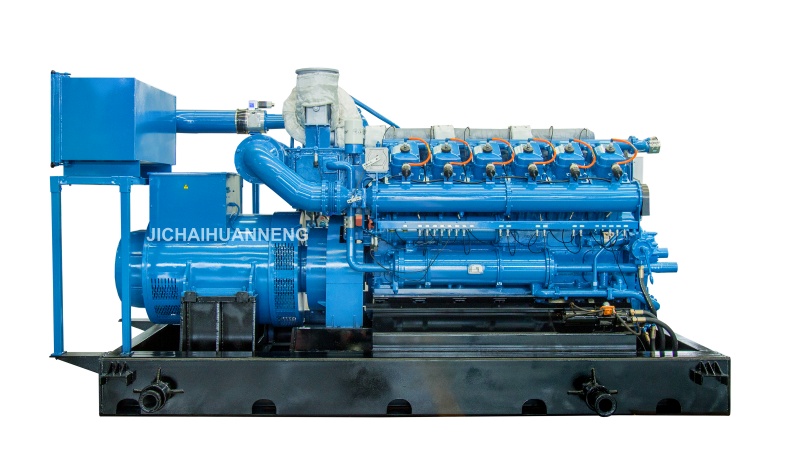

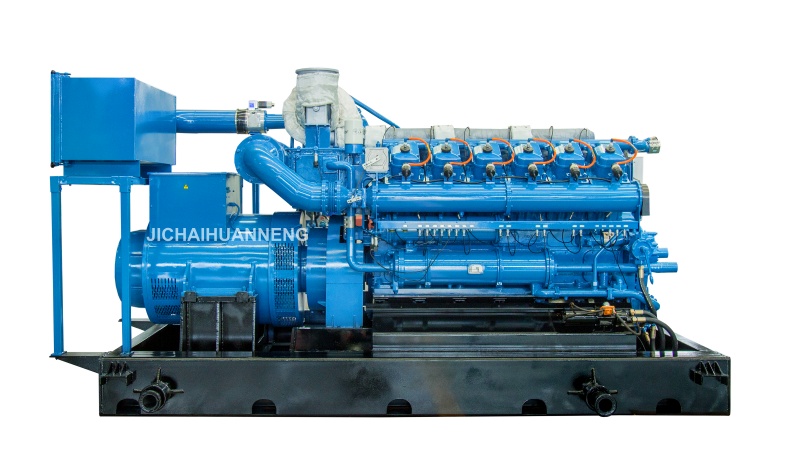

700kw LNG CNG Gas Engine generator

High quality, long usage life, easy operation, low maintenance cost, high intelligence with low engine speed, low fuel consumption, low gas quality requirement, tough environmental adopt ability, high stability and low fluctuation.

700kw LNG CNG Gas Engine generator is equipped with 12V190ZLT Gas engine It is consisted of brush-less three-phase synchronous alternator, which is produced in China with Siemens technology and Control Panel made by advanced manufacturing plant.

Main parameters of gas engine generator

Model of genset | 700GF-T |

Model of engine | 12V190ZLT-2 |

Model of alternator | 1FC6 Series |

Coupling method | |

Rated speed(r/min) | 1000 |

Rated power(kW/KVA) | 700/850 |

Rated voltage(V) | 400 |

Rated current(A) | 1281 |

Rated frequency(Hz) | 50 |

Rated power factor | 0.8 lagging |

Voltage regulation | Automatic |

Supply connecting | 3 phase 3wire |

Governor | EGS-06 (WOODWARD) |

Control model | Remote electric control, Hand control |

Starting method | 24V DC electric starting motor |

Cooling method | Water cooling system |

Electrical efficiency | 40.4% |

Heat Consumption | ≤ 9500kJ/kWh |

Net weight(kg) | 27000 |

Requirements for fuel gas

In order to ensure its reliable and stable operation of the generator set, the requirements for the natural gas quality is as follows:

——Natural gas should be dehydrated without any water, crude oil & clean oil

——Natural gas pressure 100~400kPa;

——Natural gas temperature -20~40℃;

——Total sulfur content less than 200mg/m3.

Note: Gas volume is under standard condition with 100kPa atmosphere, 20℃ambient temperature,30% relative moisture.

Requirements for cooling water

Soften water is required by high temp and low temp engine circulation system. Cooling water should be lightly alkaline clean water without any corrosive compound, such as chloride,sulfate or acid etc.

Certification