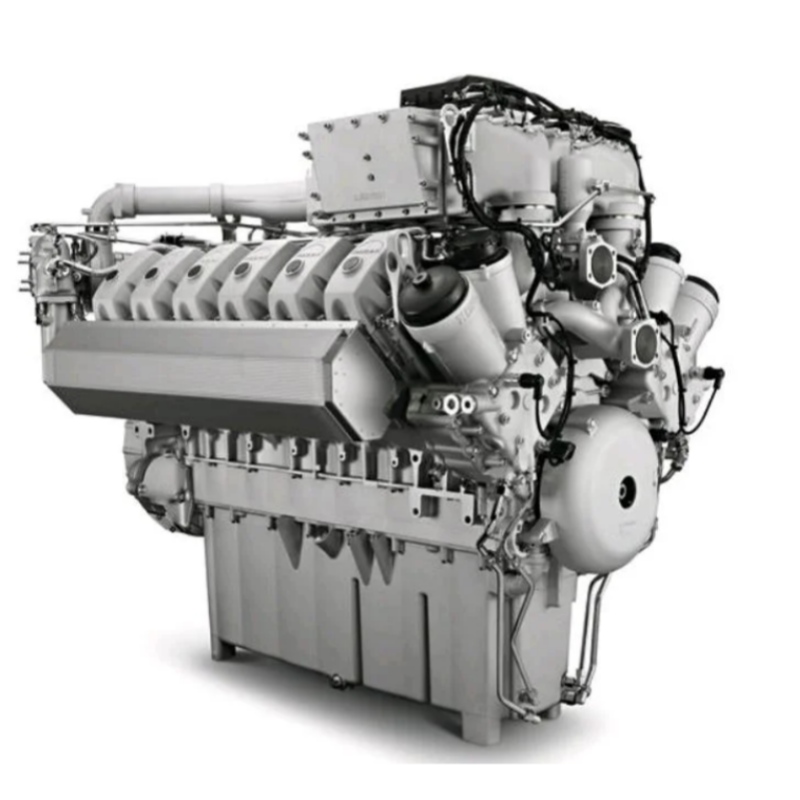

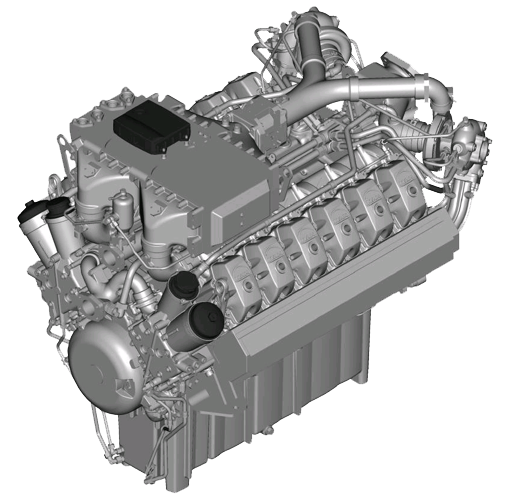

1MW Silent Container Type Gas Generator Set With German MAN Engine

1) Comprehensive Monitoring and Protection

2) Complete Data Collection

3) Operation Control and Protection

4) Automatic Air-fuel Ratio Control Algorithm

5) Automatic Protection

6) Overload and short circuit protection

7) Reverse power protection

8) Automatic Process Control

9) Data Communication and Man-machine Interaction

10) Advanced Speed Control Performance

Skid-mounted is that the cooling system, gasoline decompression system, fuel filtration system, alarm system, operation system, low-voltage distribution system, noise controlling system, and so forth are built-in on a container. The modular format of genset is an best producing answer for oil field, mining and different subject projects.

Specification of 1000kW Skid-mounted Genset

Specification of 1000kW Skid-mounted Genset

| Genset model | 1000GF-T |

| Output in parallel | 1000KW,50Hz ,400V |

| Component | 2*500kW |

| Container size(length*width*height) | 11000×2800×2590mm(for reference) |

| Weight | 17 t |

| Specification of 500kW Genset | |

| Model | 500GF-T |

| Power | 500kW/625kVA |

| Frequency | 50HZ |

| Engine model | E3262LE202 |

| Generator model | H20-6AB600/EG500 |

| Rated speed | 1500r/min |

| Rated voltage | 400V |

| Cooling method | closed |

| Dimension(length*width*height) | 3800×1200×1578mm |

| Weight | 3000Kg |

| Standard | GB/T9583.1-99 |

Technology Specification of 1000kW Skid-mounted Genset

| Model | E3262LE202 |

| Applicable gas type | Natural gas, biogas |

| Type | Vertical, inline, water-cooled, four-stroke |

| Intake method | Turbocharged |

| Number of cylinder | 12 |

| Bore×stroke | 132×157mm |

| Displacement | 25.78 L |

| Compression ratio | 12:1 |

| Fuel system | Zero pressure vale + Venturi eletric mixer |

| Ignition system | Digital ignition |

| Rated power | 500kW |

| Rated speed | 1500r/min |

| Fuel pressure | 5-15kPa |

| Heat efficiency | 40.4% |

| Steady state regulation rate | ≤0.5% |

| Applicable altitude | ≤1000m |

Technology Specification of alternator

| Alternator | H20-6AB600 |

| Rated voltage | 400 V |

| Rated frequency | 50 HZ |

| Rated speed | 1500 r/min |

| Power | 625/500KW |

| Insulation level | H |

| Power factor | 0.8 |

| Voltage adjustment method | AVR |

| Voltage regulation | ±2% |

| Excitation mode | Brushless self-excitation |

| Wiring | 3P4W |

| Connection | Y |

| Insulation level | H |

| Protection level | IP23 |

| Implementation standard | GB755\BS500\IE34-1 |

| Ambient temperature | 50ºC |

Feature

1) Comprehensive Monitoring and ProtectionThe gas control system is used to monitor the operation of genset, and it achieves the functions of island operation, parallel operation, grid connection, remote-monitoring etc. Long-term operation verifies its great stability.

2) Complete Data CollectionThe operation parameters and events of engine could be collected and recorded. It includes exhaust temperature, lubrication oil temperature, cooling water temperature, oil pressure, MAP, MAT, gas pressure, mixer position feedback, rotation speed, etc.

3) Operation Control and ProtectionComap controller with strict operation control and protection strategy could avoid overload, overlimit, overspeed and other defaults effectively to ensure safety operation through the cooperation of control software and physical circuits.

4) Automatic Air-fuel Ratio Control AlgorithmAutomatic air-fuel ratio control algorithm based on the whole operating conditions has the function of air-fuel ratio self calibration and closed loop control, ensuring efficient combustion. It consists of control methods at different operating stages (starting, idling, empty load, loading, load shedding, etc.)

5) Automatic Protection: the gas would be cut off automatically and audio visual alarm would be sent out when the defaults(low oil pressure, over-voltage, under-voltage,over-speed, high water temperature, low speed, startup failure,etc,) occur.

6) Overload and short circuit protection: the function is achieved through output switches.The protection device could feedback quickly and reliably.

7) Reverse power protection

8) Automatic Process Control

The automatic process control system starts with push-button. It could connect to the grid and control power at the same time, and adjusts control parameters automatically to keep the genset running in optimal state. The genset could control automatically or manually and manual control could intervene in the process of automatic control at any time.

9) Data Communication and Man-machine Interaction

The man-machine interaction makes it easy to operate on a single machine; multiple communication interface such as Ethernet, modbus rtu, etc to meet different needs.

10) Advanced Speed Control Performance: the advanced speed control actuators is used and speed closed-loop control. The steady-state speed fluctuation rate is ≤ 1%, and the transient response speed is fast.