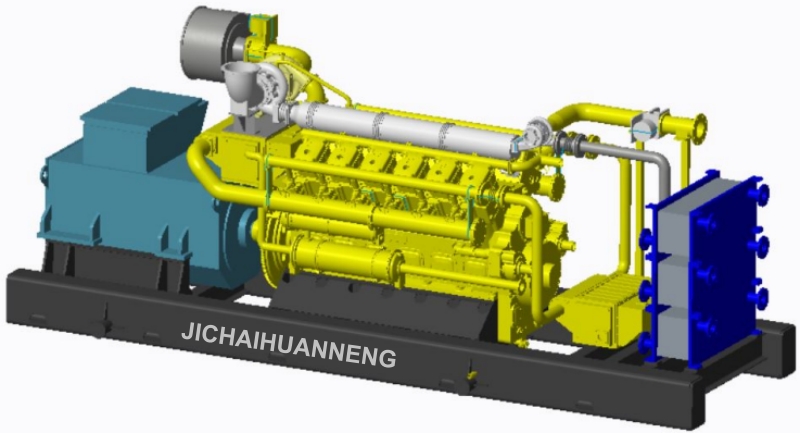

600KW Biomass Genetator

This biomass gas generator set adopts 12V190ZL engine, which is one sort of highly intelligent,low heat consumption, high reliability, low emission, especially designed for biomass gas with high contents of hydrogen.

1.Specially design

Engine 12V190ZL is specially designed for low heat value gas with one-button start function.

2. Precise control of air-fuel ratio

It can realize the air-fuel ratio control algorithm based on the high-speed controller with imported air-fuel ratio control actuators. The air-fuel ratio control is precise and the adjustment speed is fast. The engine automatically monitors the combustion status in real time and the central control unit issues instructions to adjust the gas channel, thereby changing the gas intake, and automatically adjusting the mixing ratio. Through this technology, the temperature of the cylinder of the unit can be controlled below 400℃,which significantly reduces the heat load and significantly improves the reliability of the operation of the unit, especially to prevent knockig.

3. High-energy digital ignition system

Using German Motor-tech high-energy digital ignition system, real-time adjustment of ignition advance angle can be realized to prevent knocking and high-temperature in cylinder, which can ensure the safe operation of the generator set.

4. Centralized control of gensets

Through centralized control, digital collecting generator sets feedback signals and adjust the air-fuel ratio automatically. It can reduce manual operation work load and avoid mis-operation during starting.

5. Measurement protection

All parameters such as cylinder temperature and exhaust temperature can be measured and the

engine protection is complete.

6. Automatic grid connection

Automatically match the phase, adjust the frequency and voltage, and realize the direct grid connection function of power generation.

1、operation environment

1.1 Environment temperature:-25℃~40℃

1.2 Relative humidity: 95%

1.3 Ambient atmosphere pressure: 100kPa

2、Requirement on the biomass

Volume content of hydrogen in gas:≤60%;H2S≤200mg/Nm3;NH3≤20mg/Nm3 ;

Gas temperature: ≤40 ℃;

Engine air intake pressure: 100~400kPa,

Rate of pressure change: ≤1kPa/min;

Tar content: ≤50mg/Nm³

Impurity granularity: ≤50μm,

impurity content: ≤30mg/Nm³

Water content of biomass: ≤40mg/Nm³, no condensed water, moisture is less than 80%.

3、500GF-M Generator technical parameters

No. | Item | Main technical data |

1 | 600GF-M | |

Type | ||

2 | 625kW | |

Rated power | ||

3 | 400/230 V | |

Rated voltage | ||

4 | ||

Rated power factor | 0.8 Lag | |

5 | 50 Hz | |

Rated frequency | ||

6 | 902 A | |

Rated current | ||

7 | ±2.5% | |

Stabilized voltage regulation | ||

8 | -15%~+20% | |

Instantaneous voltage regulation | ||

9 | 1.5 s | |

Voltage recovery time | ||

10 | 10-15% | |

Fluctuation of voltage | ||

11 | 0~15%可调 | |

Stabilized frequency regulation | 0~15% Adjustable | |

12 | ±10% | |

Instantaneous frequency regulation | ||

13 | ≤7 s | |

Frequency recovery time | ||

14 | 5% | |

Fluctuation of frequency | ||

15 | ||

Exciting method | Brush-less | |

16 | 12V190ZL | |

Type of gas engine | ||

17 | SIEMENS Series | |

Type of generator | ||

18 | ||

Coupling mode | Elastic | |

19 | Rated speed | 1000 r/min |

20 | ||

Starting method | 24V DC electric motor starting | |

21 | GCBP1—600M | |

Model of control panel | ||

22 | ||

Control mode | Electrical start | |

23 | ||

Voltage regulation | Automatic | |

24 | ||

Wiring method | 3 phase-4 wires | |

25 | 80~100kPa | |

Intake natural gas pressure | ||

26 | 11000KJ/KW·h | |

Heat consumption | ||

27

| Specific oil consumption | ≤0.6g/KW·h |

28 | Governor | electrical governor |

29 | Noise | 105 dBA |

Noise 105 dBA | ||

30 | Generator weight | 12500 kg |

31 | Overall dimension(L×W×H) | 6025×2100×2300 mm |

3.3 Control panel

Rated voltage:400V

Rated frequency:50HZ

Rated current: 902A

Rated power factor: 0.8(Lag)

4、 Safety and protective devices of the generator set

4.1 When facing over speed and low oil pressure, the genset shall be:

A. Engine stop

B. Main breaker GCB trip

C. Lamp on

D. Buzzer sound

4.2 When facing reverse power and over current, the genset shall be:

A. Main breaker GCB trip

B. Lamp on

C. Buzzer sound

4.3 When high water temperature, high oil temperature and overload, genset shall be :

A. Lamp on

B. Buzzer sound

C. Engine stop

5、 Monitor function of the generator

5.1 Remote monitor function on the panel

A. alternating current

B. frequency

C. power factor

D. power

E.direct voltage

F. cumulative running time

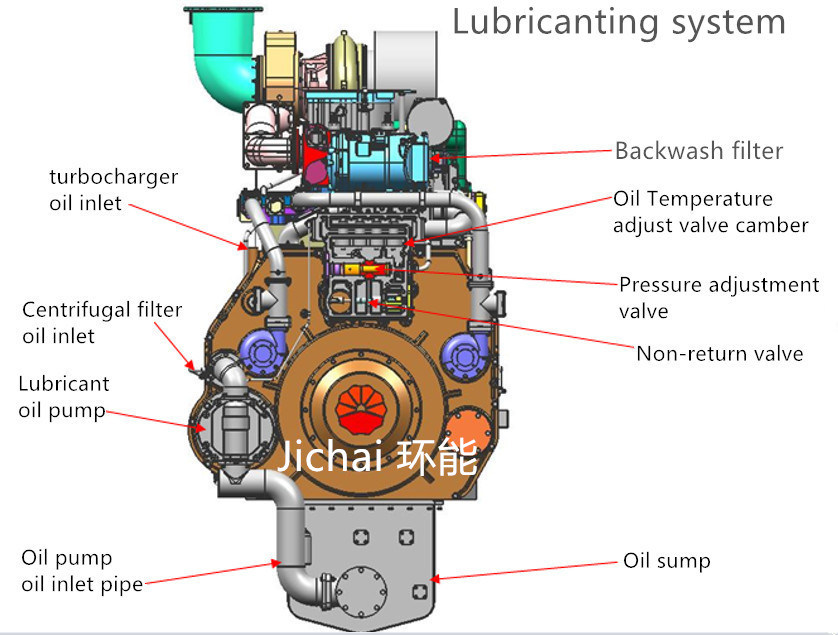

5.2Gas engine monitor function

A. Exhaust temperature

B. Oil temperature of engine

C. Water outlet temperature of engine

D. Oil pressure in engine main oil passage

E. Oil pressure before oil filter

F Oil inlet pressure of turbocharger