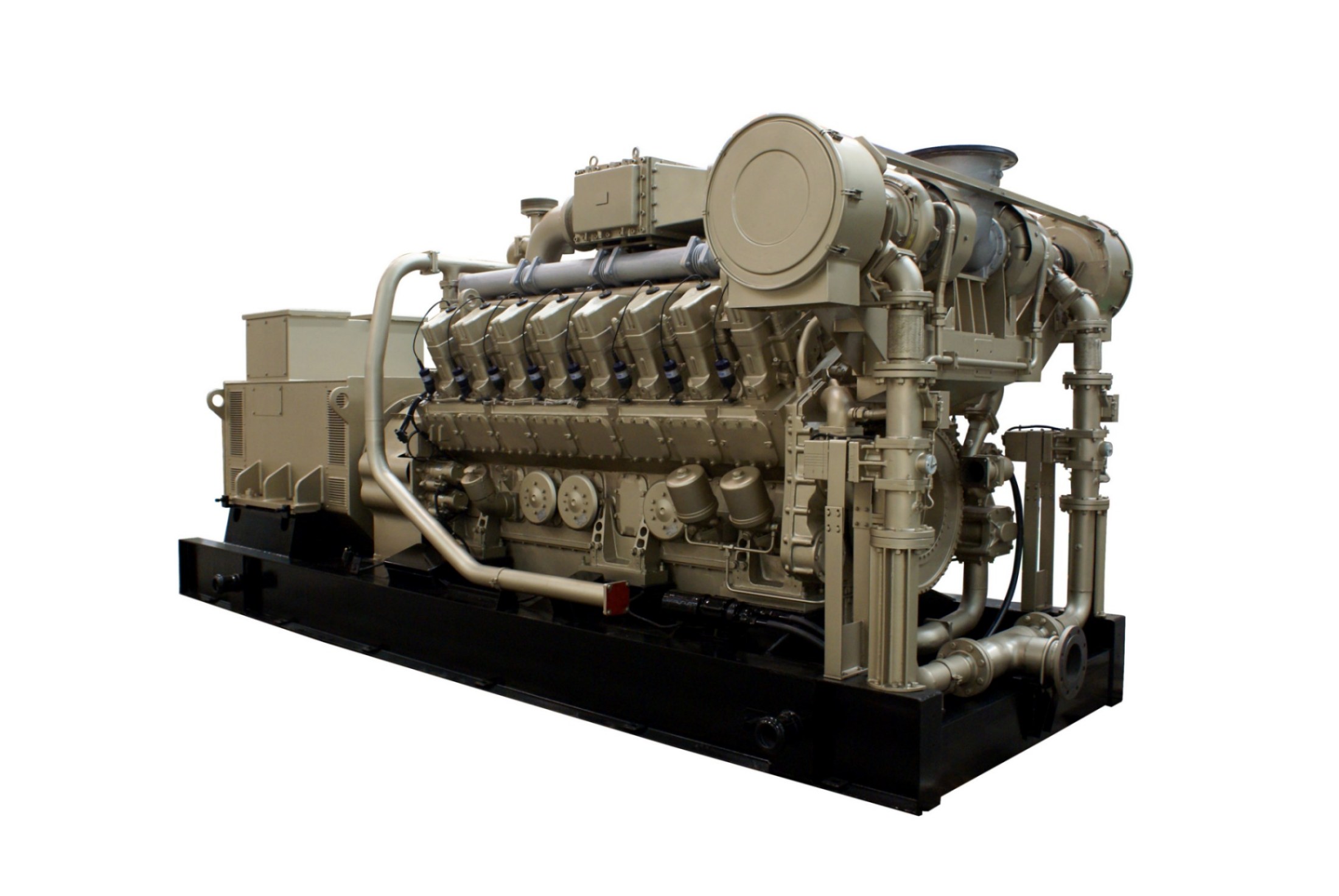

1500kW Biogas Engine Generator

1. Mixture technology before turbocharger, gas and air within compressor to suit for low-pressure gas.

2. Lean ignition technology, adopts WOODWARD E6 control system to control air-fuel ratio accurately.

3. Gas single injection and air-fuel ratio closed circuit control system to realize the control of λ.

4. Efficient and reliable input and output system design, adopts advanced high pressure ratio and turbocharger with large capacity to enlarge its circulation area and increase input efficiency.

5. Use high power, highly reliable ignition system to ensure its stable and even ignition of each cylinder.

This natural gas generator adopts -L20V190ZLT-1 engine, which is one sort of highly intelligent, low heat consumption, high reliability, low emission, long lifetime 20V gas engine designed and manufactured with the 16V gas engine as the model sample.. L20V190ZLT-1 electrical control and external mix engine owns speed 1000r/min, single unit power 2000kW. Instantaneous power can up to 2200kw.

The gas engine generator system consists of a natural gas engine, a generator, a common chassis, a high elastic coupling, a control cabinet and so on. The system is equipped with a perfect system of gas inlet, DC starting and electrical control. Generator is Synchronous AC brush-less excitation generator.

Installation: indoor installation, engine and generator rigidly mounted on the chassis, the chassis is installed on the base through the transition cushion, transition between base and foundation with anchor screws, between the engine and the generator are connected by high elastic coupling.

Generator alternator: generator with domestic well-known brand synchronous alternator. The generator adopts the sliding bearing type, equipped with current transformer for generator differential protection and self-excited constant voltage (AVR).

Control box

PLC controller is assembled in the control box. Thus, it can realize logical relation between refueling and oil expulsion accurately and realize manual/automatic refueling; it has the function of oil level alarm (including oil pan and lubricating can).

Cooling system

Every generator set is equipped with a set of horizontal radiators which are used for cooling of high temperature system (cylinder liner and primary inter-cooling of the inter-cooler) and low temperature system(secondary inter-cooling of the inter-cooler and lubricating oil cooler) of the engine.

The cooling water pipeline between the horizontal radiator and the GE is produced and installed on site, and each GE is equipped with a high-temperature water temperature control valve at the factory to meet the high-temperature water cooling temperature requirements.

The horizontal radiator is equipped with a terminal box. The complete wiring of the cable from the terminal box to the cooling fan, temperature sensor and expansion water tank liquid level sensor is complete.

Genset model | 1500GF-Z |

Alternator model | 1FC series,siemens technology.Brushless excitation,Automatic voltage regulation. |

Panel model | GPL1500 |

Rated power | 1500KW |

Rated voltage | 400V/480V/6300V/10500V/13800 |

Rated frequency | 50HZ |

Rated power factor | 0.8 |

Wiring mood | 3 Phase 4 Wire/3 Phase 3 Wire |

Stabilized voltage regulation | ±2.5% |

Transient state voltage regulation | +20%(-15) |

Voltage stabilization time | ≤1.5s |

Fluctuation rate of voltage | ≤1% |

Transient state frequency regulation | ≤±10% |

Frequency stabilized time rate | ≤7s |

Fluctuation rate of frequency | ≤0.5% |

Overall dimension | 6000mm*2300mm*2800mm |

Net weight | 17000kg |

Engine model | L20V190ZLZ-2 |

Type | Four strokes,Vshape,turbocharged intercooling,spark plug ignition. |

Number of cyliner | 20 |

Bore | 190mm |

Stoke | 255mm |

Total displacement | 144.6L |

Rated speed | 1000r/min |

Rated power | 1500KW |

Idle speed | 700r/min |

Gas pressure | 10-40KPa |

Gas consumption | ≤8850kJ/kW·h |

Oil consumption | ≤0.3g/kW·h |

Exhaust tem.(before turbine) | ≤650℃ |

Water oulet temperature | ≤85℃ |

Water inlet temperature of intercooler | <45℃ |

Oil temperature | <90℃ |

Stabilized speed droop | ≤5 |

Cooling mood | Open type-cooling tower/closed type-vertical or horizontal radiator |

Lubrication method | Pressure and splash lubrication |

Starting mood | DC24V Electric Start |

Crankshaft rotation | Counter-clockwise(face to flywheel) |

Products Service

1. Professional engineers provide pre-sales technical consultation for users

2. Cooperate with users to install and debug the unit

3. Maintenance engineers are available to provide technical assistance at any time

Packing&Delivery

We normally undertake transport via bulk cargo, container, packing Standard export packing, or personalized packing as your request. We will prepare the most reasonable transportation mode in accordance to the extent of products. All merchandise have long past via strict inspection and are in excellent situation earlier than shipment. We try for one hundred percent client delight on each and every sale we close.

Production line

Other Products