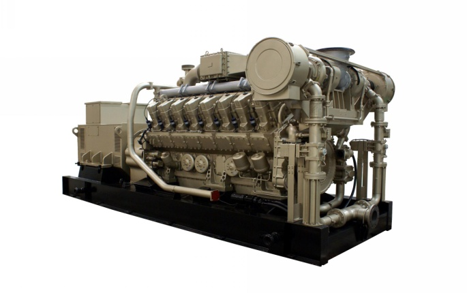

1250kVA Biogas Engine Generator

The biogas generator adopts - H16V190ZL engine, which is one type of pretty intelligent, low warmth consumption, excessive reliability, low emission, lengthy lifetime 16V fuel engine,big bore of 190mm ensures its non-stop regular electricity output,middle pace of 1000rpm ensures the provider life,natural aspiration ensures the protection of coal mattress methane transport

The biogas generator adopts - H16V190ZL engine, which is one type of pretty intelligent, low warmth consumption, excessive reliability, low emission, lengthy lifetime

![]()

MAIN SPECIFICATIONS OF GAS GENERATOR SET

Model | 1000GF-NK | Gas Engine Model | H16V190ZLZ-2 | |

Rated power | 1000kW/1250KVA | Alternator | Siemens Series | |

Rated voltage | 400 V | Starting method | 24V DC electric start | |

Rated speed | 1000rpm | Voltage regulation | Automatic | |

Rated frequency | 50Hz | Cooling Mode | Close type water cool | |

Rated current | 2164A | Heat Consumption | £ 9500kJ/kWh | |

Power factor | 0.8 Lagging | Dimension (mm) | 5998×2516×2540mm | |

Control mode | Electric control | Net Weight (kg) | 21000 |

MAIN ELECTRICAL PERFORMANCE OF THE GAS GENERATOR

Voltage | |||

Stabilized regulation | Instantaneous regulation | Recovery time | Fluctuation |

±2.5% | +15% | 2 S | 1% |

Frequency | |||

Stabilized regulation | Instantaneous regulation | Recovery time | Fluctuation |

0-5% adjustable | ≤±5% | < 7 S | 1% |

MAIN SPECIFICATIONS OF GAS ENGINE

Model | H16V190ZLZ-2 |

Rated power | 1000kW/1250KVA |

Number and layout of cylinders: | 16-cylinders, V-type, 60° included angle |

Type | Four stroke, water cooled, turbocharged and after cooled, direct injection |

Ignition type | Spark plug ignition |

Intake gas pressure required | 7-9kPa |

Bore´Stroke | 190´215 mm |

Speed Governor | Woodward Electric governor |

Oil consumption | £ 1.0g/kWh |

Total lubricating oil capacity (Liters) | 460L |

Exhaust temperature (before turbine) | £ 680 °C |

Heavy overhauling period | 56,000h |

MAIN SPECIFICATIONS OF ALTERNATOR

Alternator model | Exciting model | Insulation class | Connection | Cooling | Structure type |

1FC Series (SIEMENS) | Brushless | Class F | 3-phase, 4-wire | Air cooled | AVR and reactive droop regulator assembled in alternator |

(Kindly Noted: data shown in above table tested under standard working condition: 25 Dec C, atmospheric pressure 100kPa, relative humidity 30%, altitude <1000m.)

CONTROL PANEL

Control panel is panel type, vertical structure, model is GPL1000. Control panel is equipped with meters showing various parameters of operating status, automatic air switch and timer. All of the electric cells possess three-proof functions.

The Generator possesses the following automatic monitoring and protective functions:

A) Audio or visual alarm for:

- High oil and water temperature

- Low oil pressure

- Over current

- Short circuit

- Over-speed

- Reverse power

B) Shut-off for:

- Low oil pressure

- Over-speed

- Short circuit

- Over-speed

- Reverse power

C) Trip-off for:

- Over-current

- Short circuit

- Reverse power

The generator can not only supply power directly to load but also can be paralleled running.

OPTIONAL DEVICE

Steel Soundproof Container (sound attenuated canopy)

CHP/ Cogeneration/CCHP Trigeneration

ATS and Synchronization Parallelling Panel

Oil and Water Heater

Packing&Delivery:WOODEN CASE/PLYWOOD CASE

1) Genset would be covered with plywood boxes or cartons ;

2) Control panel, batteries, electric cables are packed with plywood boxes or cartons;

3) Exhaust pipes, engine mufflers are put in the container without packing.