Basic conditions of biogas fermentation processwaste water sewage biogas scrubber 1. Appropriate fermentation temperatureThe temperature conditions of the digester can be divided into:waste water sewage biogas scrubber 2. The temperature range of room temperature fermentation (also known as low temperature fermentation) is between 10 ºC and 30 ºC. At this temperature, the gas production can reach 0.15-0.3m3/m3. Dwaste water sewage biogas scrubber 3. The medium temperature fermentation temperature is between 30 ºC and 45 ºC.

Contact Now

Biogas power generation technology is a new energy comprehensive utilization technology that integrates environmental protection and energy conservation. It utilizes a large amount of organic waste from industry, agriculture, or urban life (such as distiller's grains, livestock manure, urban garbage, and sewage), and produces biogas through anaerobic fermentation treatment.

Contact Now

Biogas technological know-how is a new power complete utilization technological know-how that integrates environmental safety and electricity conservation. It makes use of a massive quantity of natural waste from industry, agriculture, or city existence (such as distiller's grains, cattle manure, city garbage, and sewage), and produces biogas thru anaerobic fermentation treatment.

Contact Now

600kW Biogas generator is a new power complete utilization technological know-how that integrates environmental safety and electricity conservation. It makes use of a massive quantity of natural waste from industry, agriculture, or city existence (such as distiller's grains, cattle manure, city garbage, and sewage), and produces biogas thru anaerobic fermentation treatment.

Contact Now

The engine's necessities for cooling water are: softened water or antifreeze have to be used for cooling in the excessive and low temperature cycles of the engine, and barely alkaline easy water have to be chosen for the cooling water, and ought to now not comprise corrosive compounds, such as chlorides, sulfates or acid etc.Its important warning signs are as follows:Hardness 0.7~5.3me/LChloride ion content material <150mg/LPH cost 7~8.5The radiator manage&nb

Contact Now

1. Increased Efficiency: This reduces downtime and production costs.2. Improved Productivity: Automation systems can monitor and adjust processes to eliminate inefficiencies, improve accuracy, and increase output. This results in improved productivity and higher profits.3. Enhanced Safety: Automation systems can reduce the risk of accidents by monitoring critical processes and taking preventive measures in the event of system failure or malfunction.4. Cost Savings: Automatic control systems can help reduce energy consumption, lower labor costs, minimize waste, and increase equipment lifespan.

Contact Now

The spark plug broadly used in gas engine generator , biogas generator,gas generation, coking gas generation, coke oven gas, organic gasoline production, waste warmness complete utilization generator.The product overall performance is stable, has been broadly used in oil discipline (natural gas), gasoline layer (coal mine gas), biogas, blast furnace gas, coke oven gas, fuel furnace gas, biomass gas, waste warmness complete utilization of generator ignition field.In addition,

Contact Now

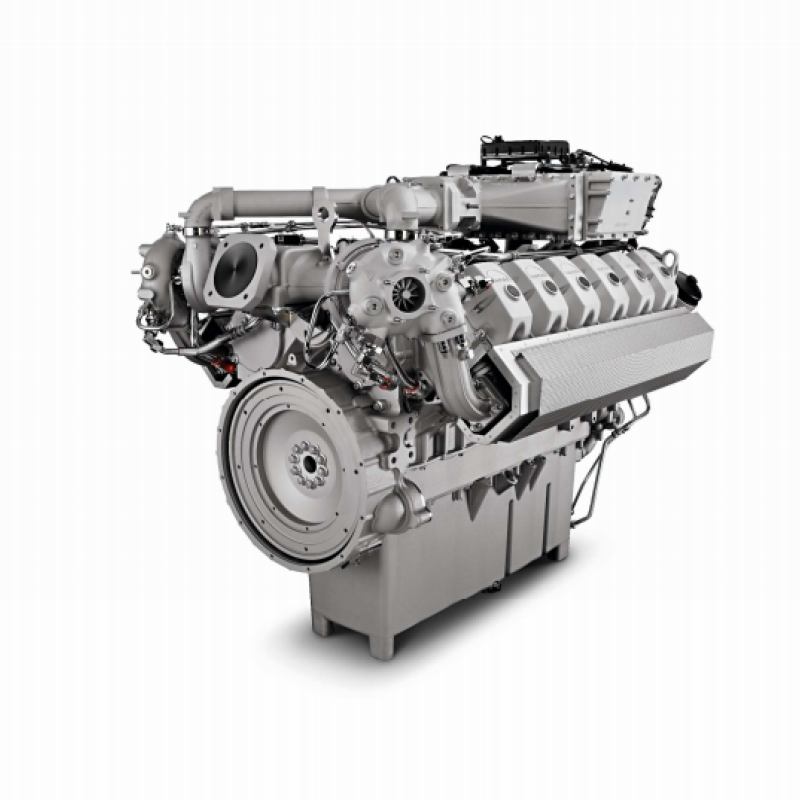

MAN Engines offers low-pollution gas engines for purely electrical power generation and cogeneration. The power range extends from 37 kW to 750 kW with natural gas and from 68 kW to 750 kW with special gas (biogas, landfill gas, sewage gas). The MAN engines developed especially for the application with natural and special gas excel through their ultimate reliability and highest energy efficiency.

Contact Now

MAN engines for natural gas and special gas (biogas, landfill gas, sewage gas) ensure security of supply – they have been thoroughly tested and optimized in field trials. The engines have proven themselves through their robustness, combined with high operating hours in peak-load and continuous operation, in the agricultural and municipal sectors, in hotels and hospitals as well as in numerous other industries.

Contact Now

1500kW biogas generator sets are designed on the groundwork of over one hundred records of western producing set manufacturing, in strictly accordance with ISO rules to produce.It adopts superior high-performance engines, generators, imported steady stress & microcomputer manage gadget to make our merchandise and use excessive water resistant processed technological know-how to occupy the home and overseas markets.Rated power1500kWRated voltage400

Contact Now

MAN Engines offers low-pollution gas engines for purely electrical power generation and cogeneration. The power range extends from 37 kW to 750 kW with natural gas and from 68 kW to 750 kW with special gas (biogas, landfill gas, sewage gas). The MAN engines developed especially for the application with natural and special gas excel through their ultimate reliability and highest energy efficiency.

Contact Now

The biogas generator adopts - H16V190ZL engine, which is one type of pretty intelligent, low warmth consumption, excessive reliability, low emission, lengthy lifetimeMAIN SPECIFICATIONS OF GAS GENERATOR SETModel1000GF-NKGas Engine ModelH16V190ZLZ-2Rated power1000kW/1250KVAAlternatorSiemens SeriesRated voltage400 VStarting method24V DC electric startRated speed1000rpmVoltage regulationAutomaticRated frequency50HzCooling ModeClose type water coolRated current2164AHeat Consumption£ 9500kJ/kWhPower factor0.8 LaggingDimension (mm)5998×2516×2540

Contact Now

MAN Engines offers low-pollution gas engines for purely electrical power generation and cogeneration. The power range extends from 37 kW to 750 kW with natural gas and from 68 kW to 750 kW with special gas (biogas, landfill gas, sewage gas). The MAN engines developed especially for the application with natural and special gas excel through their ultimate reliability and highest energy efficiency.

Contact Now

Biogas combustion energy technology is a biogas utilization science that has emerged with the non-stop improvement of large-scale biogas digesters and complete utilization of biogas. It makes use of the biogas generated through anaerobic fermentation remedy on the engine and is geared up with a complete electricity era gadget to generate electrical energy and warmth energy.

Contact Now

Biogas combustion power generation is a biogas utilization technology that has emerged with the continuous development of large-scale biogas digesters and comprehensive utilization of biogas. It uses the biogas generated by anaerobic fermentation treatment on the engine and is equipped with a comprehensive power generation device to generate electricity and heat energy.

Contact Now

MAN Engines offers low-pollution gas engines for purely electrical power generation and cogeneration. The power range extends from 37 kW to 750 kW with natural gas and from 68 kW to 750 kW with special gas (biogas, landfill gas, sewage gas). The MAN engines developed especially for the application with natural and special gas excel through their ultimate reliability and highest energy efficiency.

Contact Now

The MAN Gas Engine Genenrator provides low-pollution gasoline engines for in basic terms electrical technology and cogeneration. The electricity vary extends from 37 kW to 750 kW with herbal fuel and from sixty eight kW to 750 kW with extraordinary gasoline (biogas, landfill gas, sewage gas).

Contact Now

Biogas strength technology science is a new power complete utilization technological know-how that integrates environmental safety and strength conservation.

Contact Now

The 8700kW Biogas Generator is designed and manufactured to be excessive quality, lengthy utilization life, convenient operation, low protection cost, excessive talent with low engine speed, low gas consumption, challenging environmental adaptability, excessive steadiness and low fluctuation.

Contact Now

The 500kW Biogas Generator is equipped with M12V190ZL Gas engine as original power,which is designed and manufactured to be high quality, long usage life, easy operation, low maintenance cost, high intelligence with low engine speed, low fuel consumption, low gas quality requirement, tough environmental adaptability, high stability and low fluctuation.

Contact Now

The 500kW Biogas Generator is geared up with 12V190ZL Gas engine as unique power,which is designed and manufactured to be excessive quality, lengthy utilization life, handy operation, low upkeep cost, excessive brain with low engine speed, low gas consumption, low fuel high-quality requirement, difficult environmental adaptability, high balance and low fluctuation.

Contact Now

Jichai biogas generator set is designed and manufactured to be excessive quality, lengthy utilization life, convenient operation, low protection cost, excessive Genius with low engine speed, low gas consumption, low fuel first-class requirement, difficult environmental adaptability, excessive steadiness and low fluctuation.

Contact Now

The biogas generator adopts - L20V190ZL engine, which is one type of pretty intelligent, low warmth consumption, excessive reliability, low emission, lengthy lifetime 20V fuel engine.Genset model1600GF-ZAlternator model1FC series,siemens technology.Brushless excitation,Automatic voltage regulation.Panel modelGPL1600Rated power1600kWRated voltage400V/480V/6300V/10500V/13800Rated frequency50/60HZRated power factor0.8Wiring mood3 Phase 4 Wire/3 Phase 3 WireStabilized voltage regulation±2.5%Transient state voltage regulation+20%(-15)Voltage stabilization time≤1.5sFluctuation rate of voltage≤1%Tran

Contact Now

The biogas generator adopts - L20V190ZLT gas engine, which is one type of pretty intelligent, low warmth consumption, excessive reliability, low emission, lengthy lifetime 20V gas fuel engine,big bore of 190mm ensures its non-stop regular electricity output,middle pace of 1000rpm ensures the provider life.Genset model 1600GF-ZAlternator model1FC series,siemens technology.Brushless excitation,Automatic voltage regulation.Panel modelGPL1600Rated power1600KWRated voltage400V/480V/6300V/10500V/

Contact Now